Are you in the vape packaging industry? Want to ensure your products meet the highest standards? Look no further!

This article reveals the top 12 quality control measures in vape packaging that you need to implement. From inspecting materials to verifying designs and checking printing accuracy, we’ve got you covered.

Don’t risk compromising safety or regulatory compliance. Follow these measures to guarantee dimensional accuracy, product safety, and packaging seal integrity.

It’s time to step up your quality control game!

Key Takeaways

- Quality control measures in vape packaging include examining bottles and caps for high-quality, durable plastic, ensuring materials are resistant to leakage, and checking for harmful chemicals or toxins.

- Printing and color verification is important to ensure text and graphics are clear and legible, colors match the approved design, and consistent colors aid brand recognition and convey brand identity effectively.

- Packaging integrity and safety measures involve accurate measurement of dimensions, proper placement of labels and logos, conducting durability tests such as drop, vibration, and compression testing, and adhering to regulatory standards.

- Customer satisfaction and trust can be enhanced through visible and legible information, conveying professionalism and trustworthiness, maintaining consistency in odor and taste, and building trust with customers through compliance with regulatory authorities.

Material Inspection in Custom Vape Packaging

Inspecting the materials used in custom box packaging is crucial to ensure the safety of the products. This includes examining the bottles and caps to ensure they are made of high-quality plastic that is durable and resistant to leakage. It is important to check if these materials are free from any harmful chemicals or toxins that could potentially harm consumers. Look for certifications or safety labels on the packaging as well to ensure compliance with industry standards. A thorough inspection is essential to ensure that the vape products meet the highest quality and safety standards before they are sent out to customers.

Design Verification of Customized Vape boxes

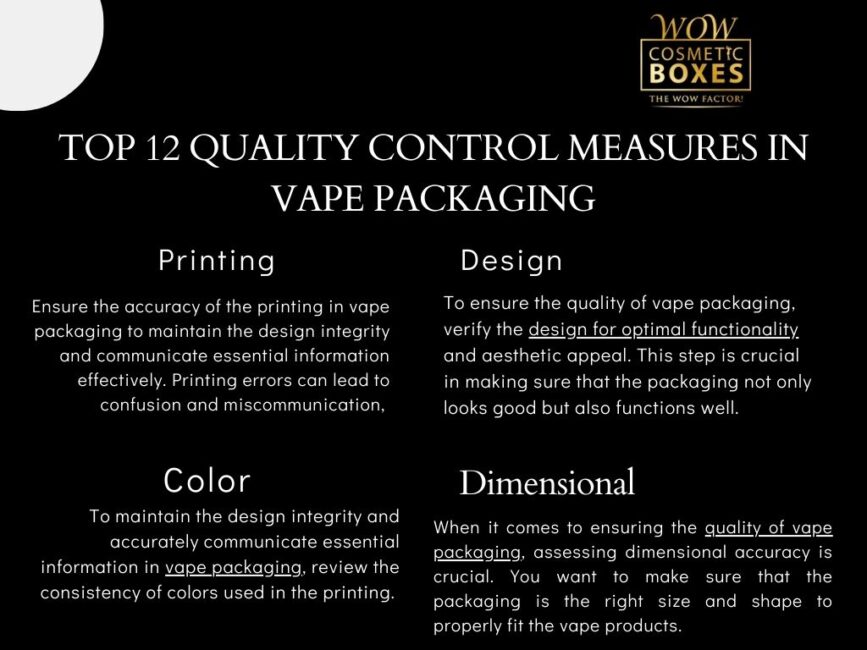

To ensure the quality of vape packaging, verify the design for optimal functionality and aesthetic appeal. This step is crucial in making sure that the packaging not only looks good but also functions well. Here are three reasons why design verification is important:

- Ensures the packaging is user-friendly: By verifying the design, you can make sure that the packaging is easy to open, close, and use. This can enhance the overall user experience and prevent frustrations.

- Enhances brand image: A well-designed vape packaging can leave a lasting impression on your customers. It can convey professionalism, creativity, and attention to detail, which can help build trust and loyalty.

- Differentiates your product: In a sea of vape products, a unique and visually appealing design can make your product stand out. It can attract attention, spark curiosity, and increase the chances of purchase.

Printing Accuracy Check Of Custom Vape Boxes

Ensure the accuracy of the printing in vape packaging to maintain the design integrity and communicate essential information effectively. Printing errors can lead to confusion and miscommunication, so it’s crucial to check for accuracy.

Start by examining the text and graphics for any smudges, blurriness, or misalignment. Make sure that all the information is legible and easy to read. Check for any spelling or grammatical mistakes that could impact the clarity of the message.

Verify that the colors used in the printing match the approved design. Any discrepancies could affect the overall appearance of the packaging.

Color Consistency Review for Custom Vape Box Packaging

To maintain the design integrity and accurately communicate essential information in vape packaging, review the consistency of colors used in the printing. This ensures that the colors on the packaging are consistent throughout, avoiding any discrepancies that may confuse or mislead consumers. By checking the color consistency, you can ensure that the brand’s identity and message are effectively conveyed.

Here are three reasons why color consistency review is crucial:

- Brand recognition: Consistent colors help customers easily recognize and associate the product with your brand, building brand loyalty and trust.

- Professionalism: Accurate colors demonstrate attention to detail and professionalism, making your packaging look polished and well-executed.

- Emotional connection: Colors have the power to evoke emotions. Consistent colors can create a specific mood or feeling, enhancing the overall appeal of the product and connecting with customers on a deeper level.

Dimensional Accuracy Assessment of Vape boxes

How accurately can you measure the dimensions of the vape packaging using a ruler?

When it comes to ensuring the quality of vape packaging, assessing dimensional accuracy is crucial. You want to make sure that the packaging is the right size and shape to properly fit the vape products.

To assess dimensional accuracy, you can use various tools such as rulers, calipers, or measuring tapes. These tools allow you to measure the length, width, and height of the packaging.

It’s important to be precise in your measurements to avoid any issues with the fitment of the products. By conducting thorough dimensional accuracy assessments, you can guarantee that the vape packaging meets the desired specifications and provides a seamless experience for consumers.

Label and Logo Placement Verification for vape packaging boxes

Check the positioning of labels and logos on your vape packaging to ensure they’re accurately placed. This step is crucial to maintaining the overall aesthetic appeal of your product. Here are some reasons why you should pay close attention to label and logo placement:

- Distorted placement can make your packaging look unprofessional, causing potential customers to doubt the quality of your product.

- Labels and logos that are off-center or too close to the edges can give the impression of carelessness, making it harder for customers to trust your brand.

- Accurate placement of labels and logos ensures that important information, such as nicotine content and flavor, is easily visible and legible, providing clarity to your customers.

Packaging Durability Testing of Customized Vape Packaging Boxes

Ensure the durability of your vape packaging by conducting thorough testing to confirm its ability to withstand various conditions.

Packaging durability testing is crucial to ensure that your vape products reach the customers in pristine condition. This testing involves subjecting the packaging to different stress factors, such as pressure, temperature, and moisture, to simulate real-life scenarios. By doing so, you can identify any weaknesses or vulnerabilities in the packaging and make necessary improvements.

Common tests include drop testing, vibration testing, and compression testing. Drop testing checks if the packaging can withstand accidental falls during transportation. Vibration testing assesses the packaging’s ability to withstand vibrations during shipping. Compression testing determines if the packaging can withstand the weight placed on top of it.

Odor and Taste Evaluation of customized boxes for vape

Evaluate the odor and taste of your vape products to ensure they meet the desired quality standards. It’s important to make sure that your vapes smell and taste good because no one wants to inhale something that’s unpleasant.

Here are a few things to consider when evaluating the odor and taste:

- Freshness: Your vape products should have a fresh and inviting smell. A stale or musty odor can be a major turnoff for customers.

- Flavor accuracy: The taste of your vapes should match the flavors you advertise. Customers expect a certain taste, and if it doesn’t deliver, they’ll be disappointed.

- Consistency: Every batch of your vape products should have the same odor and taste. Inconsistencies can lead to customer complaints and loss of trust.

Product Safety Assessment of custom boxes

To ensure the quality and safety of your vape products, it’s important to assess their overall safety. This means conducting thorough checks to identify any potential hazards or risks.

One key aspect of product safety assessment is examining the materials used in the vape packaging. Make sure the packaging is made from safe and non-toxic materials that won’t contaminate the product. Check for any sharp edges or loose parts that could pose a danger to users.

Another important factor to consider is battery safety. Ensure that the batteries used in your vape products are reliable and have undergone proper testing to prevent any potential malfunctions or accidents.

Compliance With Regulatory Standards

For compliance with regulatory standards, you must adhere to all necessary guidelines and requirements. It’s important to follow the rules, because if you don’t, you could face penalties or even have your product taken off the market. Here are three reasons why you should take compliance seriously:

- Safety: Regulatory standards are put in place to ensure that vape products are safe for consumers. By following these standards, you’re protecting your customers from potential harm.

- Trust: Compliance with regulatory standards helps build trust with your customers. When they see that your packaging meets all the necessary requirements, they’ll feel confident in your product.

- Reputation: Non-compliance can damage your reputation as a company. Word spreads fast, and if people hear that your packaging doesn’t meet regulatory standards, they may avoid your product altogether.

Packaging Seal Integrity Inspection

To ensure the integrity of the packaging seals in your vape products, you need to conduct regular inspections. Checking the seal is important because it ensures that your products are properly sealed and protected from any outside contaminants. It also helps to prevent any leakage or tampering, which could compromise the quality and safety of your vape products.

During the inspection, look for any signs of damage or defects in the seal, such as cracks, tears, or gaps. It’s important to also check for proper alignment and placement of the seal. By conducting regular inspections, you can identify any issues early on and take corrective measures to maintain the quality and integrity of your vape packaging seals.

Product Labeling and Information Accuracy Check

You should ensure the accuracy of product labeling and information by conducting regular checks. It’s important to make sure that the labels on your vape products have the right information and are easy to read.

Here are some reasons why accuracy in product labeling is crucial:

- Safety: Accurate labeling helps consumers understand the potential risks and precautions associated with using the product.

- Trust: When the information on the label is correct, it builds trust with your customers, showing that you value their safety and well-being.

- Compliance: Regulatory authorities require accurate product labeling, and failure to comply can lead to legal issues and penalties.