Finding the right custom packaging supplier involves carefully considering several factors. Start by understanding the types of suppliers available—manufacturers provide basic options, while solution providers enhance design and logistics. Next, establish a realistic budget, factoring in minimum order quantities and potential discounts for long-term partnerships. Evaluate material quality by looking for certifications and options that align with consumer preferences, like eco-friendliness. Don't overlook logistics capabilities; timely delivery is key to your success. Finally, prioritize suppliers with excellent customer service. This approach guarantees a partnership that meets your unique needs, and you'll uncover further insights along the way.

Main Points

- Identify the type of supplier—manufacturer or solution provider—that aligns with your packaging needs and customization requirements.

- Establish a realistic budget considering material choices, design complexities, and potential bulk order discounts.

- Evaluate material quality through certifications and tests to ensure durability and product protection.

- Assess the logistics capabilities of suppliers to ensure timely delivery and efficient inventory management.

- Prioritize suppliers with excellent customer service for responsive support and collaborative packaging design.

Understand Supplier Types

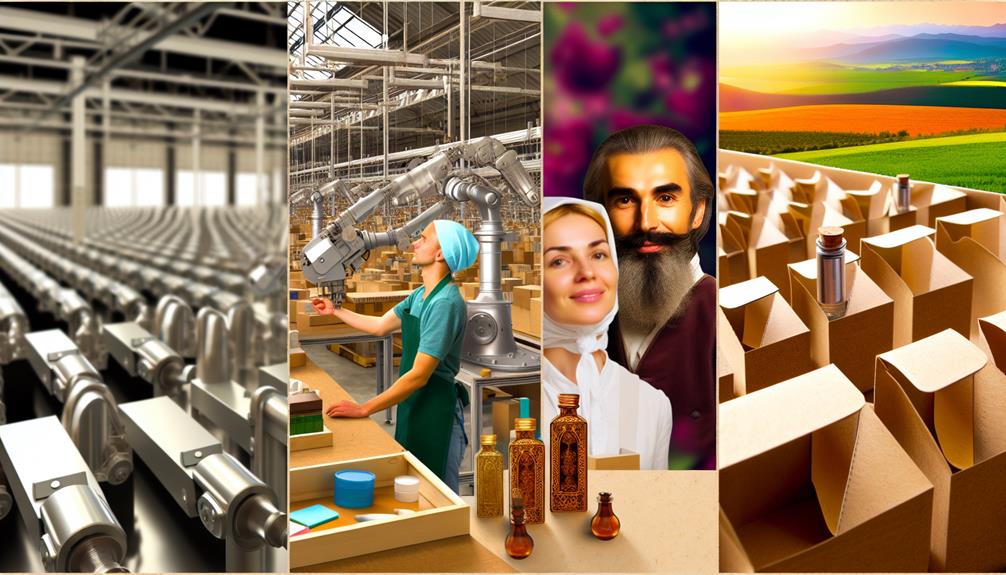

When traversing the landscape of custom packaging, understanding the different types of suppliers is essential for optimizing your choices.

Manufacturers typically focus on producing quality packaging, including custom shipping boxes, without delving into the broader aspects of your project. They may offer limited customization options, which can hinder your branding efforts.

On the other hand, solution providers offer a thorough approach, managing everything from design guidance to logistics, ensuring your packaging not only protects your product but also enhances brand recognition and loyalty.

Choosing a packaging supplier involves balancing cost-effectiveness and quality in your packaging solutions. Solution providers often possess the expertise and certifications to meet specific needs, ensuring that you comply with industry standards.

Establish Your Budget

Selecting the right custom packaging supplier naturally leads you to the significant task of establishing your budget. It's essential to set a maximum budget, guiding your supplier selection and ensuring cost-effectiveness without sacrificing quality.

For smaller businesses, the challenge of large minimum order requirements makes it imperative to identify ideal order quantities to keep packaging expenses manageable. Considering options like high-quality packaging can also impact your budget, as durable materials may come at a higher cost but provide better product protection.

Consider all aspects, including material choices and design complexities, to create a realistic budget aligned with your business goals. By comparing pricing across various suppliers, you can secure competitive pricing while evaluating the overall value and quality of their offerings.

Furthermore, building long-term partnerships with suppliers may reveal discounts on bulk orders, enhancing your budgeting strategy for future packaging needs.

Evaluate Material Quality

In evaluating material quality, it's essential to take into account the certifications and performance metrics that reflect a supplier's reliability and the durability of their packaging solutions.

Look for packaging suppliers with certifications like ISO 9001:2015, as these indicate high-quality standards. Furthermore, examining options for custom packaging solutions can provide a range of materials suited for different products.

Key tests, such as the Edge Crush Test (ECT) and Burst Strength Test, provide insight into the durability and strength of custom packaging materials, helping you avoid costly product recalls. Custom boxes designed with proper structural design can greatly reduce damage during transit, enhancing your product's integrity.

Moreover, consider eco-friendly options that don't compromise on quality, as 72% of consumers prefer them. Collaborating with packaging specialists can help you optimize material quality while staying within budget.

Assess Logistics Capabilities

Logistics efficiency plays an essential role in the overall success of your custom packaging supply chain. Assess the logistics capabilities of potential suppliers to verify they can manage shipping timelines effectively.

Look for options like air, ground, or sea transportation tailored to your specific needs. A solid logistics plan before packaging production prevents delays and guarantees timely delivery of packaged products.

Furthermore, evaluate whether the supplier offers warehousing solutions to streamline your inventory management and reduce costs. Proactive communication and problem-solving skills are significant; suppliers should address logistics issues swiftly to maintain a smooth shipping process.

Prioritize Customer Service

In regards to custom packaging suppliers, prioritizing customer service is essential for fostering strong partnerships and ensuring a smooth workflow. A packaging company that emphasizes excellent customer service stands out, as effective communication is crucial.

When suppliers are responsive to your needs, they can provide timely support for issues that arise during production or delivery, maintaining trust and satisfaction. For instance, suppliers offering customizable designs can better align with your specific brand identity.

Dedicated customer service teams enhance this experience by collaborating with you on packaging design and offering valuable customization options. Positive feedback from clients often highlights the reputation of these suppliers, influencing client choice.

With dedicated account managers providing personalized assistance, you're more likely to achieve quality prints that align perfectly with your vision. In the end, great customer service makes all the difference.