Request a Quote

-

6-8 Days turn around

-

No Die and Plate charges

-

Starting From 100 Boxes

-

Request Free Template

-

FREE Shipping

-

In House Design Support

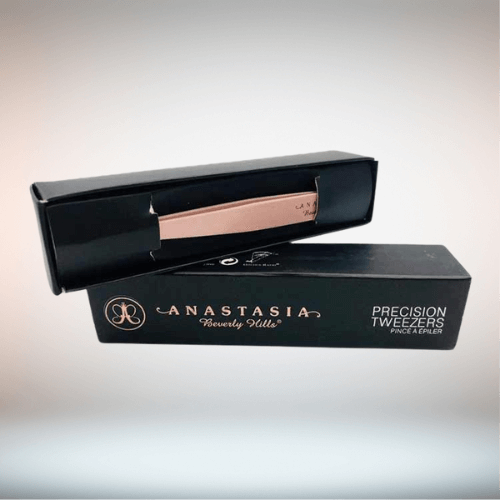

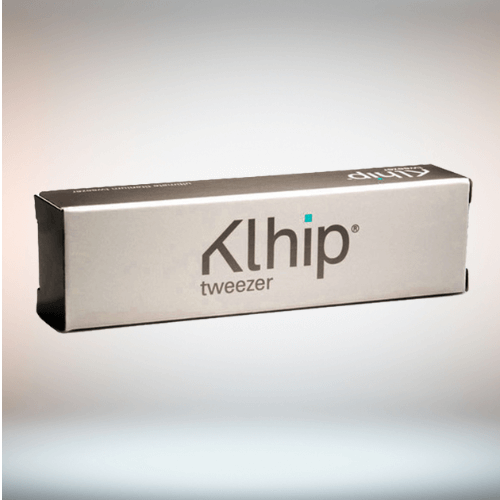

Custom tweezer packaging boxes play a pivotal role in merging practicality with visual appeal, making them essential for brands seeking to present their products compellingly while ensuring the protection of delicate tools. These boxes, crafted from robust materials such as rigid paperboard and corrugated board, can be meticulously customized to fit precise dimensions, thereby preventing damage and enhancing brand identity. What sets these packaging solutions apart are the diverse customization options and eco-friendly materials available, which not only elevate the product’s market presence but also align with sustainable practices. How do these features influence consumer perception and sales?

Importance of Custom Tweezer Boxes

The significance of custom tweezer boxes lies in their ability to enhance product appeal while providing effective protection for sharp-edged tools. These boxes are meticulously designed to offer an enchanting presentation, ensuring that tweezers are not only safely housed but also attractively displayed.

Utilizing various paper stock options such as cardboard, rigid, and corrugated materials, custom tweezer boxes are crafted to meet diverse durability and aesthetic needs.

The selection of paper stock is pivotal, as it directly impacts the box’s ability to safeguard the tweezers from external damage during transit and storage. Cardboard offers a lightweight yet sturdy option, while rigid paper stock provides enhanced protection with a premium feel. Corrugated material, known for its robustness, is ideal for ensuring the tweezers remain intact under more strenuous conditions.

These boxes are tailored to specific dimensions to perfectly accommodate the tweezers, preventing any unnecessary movement that could lead to damage. The precise fit not only secures the product but also adds to the overall professional presentation.

Custom tweezer boxes, in turn, play an essential role in both protecting the tool and elevating its market presence through thoughtful and detailed packaging solutions.

Design Features and Benefits

Elegance and functionality merge in the design features of personalized tweezer packaging boxes, offering not just an aesthetic appeal but also practical benefits that cater to both consumer and brand needs. These boxes enhance product appeal while effectively safeguarding sharp-edged tools. By utilizing various types of paper stock like cardboard, rigid, and corrugated, they provide durable and sturdy packaging solutions. The choice of material ensures that the tweezers stay secure, preventing any damage and preserving their sharpness.

To elevate the presentation, personalized tweezer packaging boxes can be adorned with a variety of finishing options, including gloss, matte, and spot UV. These finishes not only add a refined touch but also enhance the box’s tactile appeal, making it more attractive to consumers. Available in all custom sizes and shapes, these boxes can be tailored to fit any tweezer design, ensuring compatibility and top-notch protection.

Additional design elements such as embossing, debossing, and foil stamping further enhance the packaging, creating a luxurious unboxing experience. These add-ons not only showcase the brand’s attention to detail but also aid in building a premium image, ultimately increasing customer satisfaction and loyalty.

Customization Options

Tailored to meet diverse product requirements, custom tweezer packaging boxes offer an extensive range of customization options that blend functionality with aesthetic appeal. These options are designed to cater to specific needs, ensuring that the packaging not only protects the tweezers but also enhances brand presentation and customer experience.

From dimensions to shapes and styles, customization possibilities are virtually limitless. Brands can select the exact size and form that best fits their product, ensuring a snug fit and minimizing material waste.

In addition, finishing choices like gloss, matte, and spot UV give the packaging a polished final look, catering to different brand aesthetics and consumer preferences. To further elevate the packaging, various add-ons are available. Techniques such as embossing, debossing, and foil stamping can add a tactile and visual dimension to the boxes, making them stand out on retail shelves.

These enhancements not only improve the visual appeal but also contribute to a premium unboxing experience.

- Dimensions: Tailor the size and shape to fit the product precisely.

- Finishing Choices: Options include gloss, matte, and spot UV for a refined look.

- Embossing: Adds a raised texture to the design elements.

- Debossing: Creates an indented effect for a sophisticated touch.

- Foil Stamping: Offers metallic accents that highlight brand logos or text.

Material Choices

When selecting materials for custom tweezer packaging boxes, brands often prioritize options like cardboard, rigid paperboard, and corrugated board for their durability and protective qualities. These materials are specifically chosen to safeguard the sharp edges of tweezers, ensuring they remain intact and undamaged during storage and transit.

Cardboard, known for its flexibility and lightweight nature, offers extensive customization opportunities. It allows for intricate design elements and unique branding, making it an ideal choice for companies aiming to stand out in a competitive market.

Rigid paperboard, on the other hand, provides a more premium feel. Its sturdiness not only enhances the protective aspect but also adds a touch of luxury, making it suitable for high-end tweezer brands.

Corrugated board is favored for its superior strength and resilience. It is particularly effective in protecting twezers against external pressures and impacts, which is pivotal during shipping. The corrugated layers provide extra cushioning, making it a dependable choice for long-distance transit.

Finishing Techniques

Enhancing the allure of custom tweezer packaging boxes, finishing techniques like gloss, matte, and spot UV coating play a crucial role in elevating their visual and tactile appeal. These techniques are meticulously selected to not only boost the aesthetic quality but also to provide a luxurious finish that resonates with the product’s premium nature.

Gloss coating offers a shiny, reflective surface that captures light and attention, making colors appear more vivid and packaging more eye-catching. Matte coating, on the other hand, delivers a sophisticated, non-reflective finish that exudes elegance and subtlety. Spot UV coating strategically combines both gloss and matte by applying a glossy finish to specific areas, creating a striking contrast that accentuates design elements.

To further elevate the appearance and tactile experience, additional techniques can be employed:

- Embossing: Raises specific design elements, adding a 3D effect.

- Debossing: Creates an indented impression, offering a tactile contrast.

- Foil Stamping: Applies metallic foil to designs, adding a touch of luxury.

- Soft-Touch Coating: Provides a velvety texture, enhancing the sensory experience.

- Aqueous Coating: An eco-friendly option that adds a smooth, protective layer.

These finishing options cater to various preferences and profoundly impact the overall presentation and perceived value of custom tweezer packaging boxes.

Magnetic Closure Style

Incorporating a magnetic closure style into custom tweezer packaging boxes seamlessly blends functionality with sophistication, guaranteeing both secure closure and effortless access. This design choice transforms an ordinary package into a high-end marvel, epitomizing luxury and convenience. Magnetic closures, engineered by expert die-cutters, offer a sublime user experience by allowing the box to open smoothly and close securely, preventing accidental openings.

The magnetic closure system enhances the overall aesthetic appeal of the packaging, elevating the unboxing experience to a new level of elegance. By embedding discreet yet powerful magnets within the structure, the packaging maintains a sleek and minimalistic appearance while providing robust functionality. This combination of style and practicality ensures that the tweezers are always easily accessible, adding an element of delight for the user.

The magnetic closure style imbues the packaging with a premium touch, distinguishing it from conventional packaging solutions. The tactile sensation of the magnetic snap as the box closes offers a satisfying conclusion to the unboxing ritual, reinforcing the perception of quality. Essentially, the integration of magnetic closures within custom tweezer packaging boxes is an exemplary innovation, merging utility with refined elegance.

Impact on Sales

The integration of magnetic closure styles into custom tweezer packaging boxes not only exudes elegance but also has a profound impact on sales by attracting potential customers with its premium design and enhanced functionality. This sophisticated and secure packaging solution can significantly influence purchasing decisions, driving customer interest and boosting overall sales figures.

By offering a visually appealing and tactilely satisfying experience, custom tweezer packaging boxes help establish a strong brand presence and build trust with consumers. The meticulous attention to detail and protection guarantees that tweezers remain undamaged and readily accessible, enhancing customer satisfaction and repeat purchases.

Furthermore, the substantial investment in high-quality packaging design reflects the brand’s commitment to excellence, thereby elevating product appeal and encouraging customer loyalty.

- Attractive Design: Captivates consumer attention, making the product stand out on retail shelves.

- Enhanced Functionality: Magnetic closures provide secure and user-friendly access, adding to the overall appeal.

- Product Protection: Ensures the integrity of the tweezers during transportation and storage.

- Brand Trust: High-quality packaging fosters confidence and trust in the product.

- Increased Sales: The combination of visual appeal and functional benefits leads to higher sales and customer satisfaction.

In essence, custom tweezer packaging boxes play a critical role in promoting sales by offering an exceptional blend of aesthetics, functionality, and protection.

Eco-Friendly Packaging

Utilizing eco-conscious materials in personalized tweezer packaging boxes highlights a brand’s commitment to sustainability while meeting the growing consumer demand for environmentally friendly products. These packaging solutions, made from materials like cardboard, Kraft, and biodegradable paperboard, offer a harmonious combination of environmental stewardship and functional design.

Cardboard and Kraft are well-known for their strength and recyclability, ensuring that the packaging is not only sturdy but also environmentally friendly. Biodegradable paperboard takes it a step further, decomposing naturally without leaving harmful residues. By selecting these materials, brands can notably decrease their environmental footprint, aligning with global sustainability goals and legislative requirements.

The recyclability and biodegradability of these eco-friendly personalized tweezer boxes guarantee that they contribute minimally to landfill waste. This reduced environmental impact is a vital selling point in today’s market, where consumers are increasingly prioritizing sustainability in their purchasing decisions.

By choosing eco-friendly packaging, brands can enhance their image as responsible and forward-thinking, nurturing customer loyalty and trust. In essence, the use of eco-conscious materials for tweezer packaging not only supports environmental preservation but also aligns with contemporary consumer values, strengthening brand reputation and market appeal.

Popular Tweezer Box Styles

Building on the principles of eco-friendly design, selecting the appropriate tweezer box style can further enhance both the functionality and aesthetic appeal of the packaging. Various styles cater to different needs, offering a blend of protection, accessibility, and visual appeal.

The Reverse Tuck End (RTE) and Straight Tuck End (STE) boxes are popular for their efficient use of material and ease of assembly. The RTE design features a tuck flap on opposite ends, providing a secure enclosure, while the STE style allows for seamless opening and closing from the same side, enhancing user convenience.

For a premium unboxing experience, Two Piece Boxes deliver a luxurious feel with a separate lid and base, ideal for high-end tweezer products. Window Style boxes incorporate transparent panels, enabling customers to view the tweezers without opening the package, thereby adding to the product’s visual appeal and reducing handling.

The 1-2-3 Bottom Boxes are structurally robust, featuring a lock mechanism at the base that ensures the tweezers remain securely in place during transit. Finally, customized packaging solutions offer tailored designs to meet specific branding and functional requirements.

- Reverse Tuck End (RTE) Boxes

- Straight Tuck End (STE) Boxes

- Two Piece Boxes

- Window Style Boxes

- 1-2-3 Bottom Boxes

Frequently Asked Questions

How Can I Ensure My Custom Tweezer Boxes Meet Shipping Standards?

To guarantee your packaging boxes meet shipping standards, use durable materials like cardboard or corrugated, apply protective coatings, incorporate add-ons for enhanced durability, and consult packaging experts to tailor dimensions and ensure compliance with industry regulations.

What Are the Cost Implications of Ordering in Bulk?

Ordering in bulk reduces the cost per unit due to discounted prices and economies of scale, thereby allowing businesses to acquire packaging supplies at a lower overall cost and achieve substantial financial benefits from larger order quantities.

Are There Minimum Order Quantities for Custom Tweezer Packaging?

Yes, minimum order quantities exist and vary among manufacturers, ranging from 100 to larger quantities. It’s important to consult specific suppliers to understand their requirements, ensuring effective planning for your packaging needs.

Can Custom Tweezer Boxes Be Designed for Multiple Tweezer Sizes?

Yes, custom boxes can be meticulously engineered to accommodate multiple tweezer sizes, offering flexibility in design to guarantee precise dimensions and a perfect fit for various lengths and styles, thereby enhancing both functionality and aesthetic appeal.

How Long Does the Production Process for Custom Boxes Take?

The production process for custom boxes typically spans 10-12 business days. Expedited options are available, reducing production time to 5-7 business days. This guarantees a timely and efficient delivery, meeting various packaging requirements.